With years of experience in textile manufacturing and rich technical capabilities, we offer exceptional solutions. The success of our customers' businesses is important to us so we always strive to stay one step ahead.

We produce

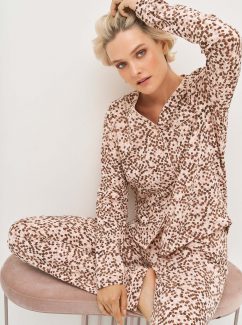

LEISUREWEAR

UNDERWEAR

FASHION

KIDS AND BABY CLOTHING

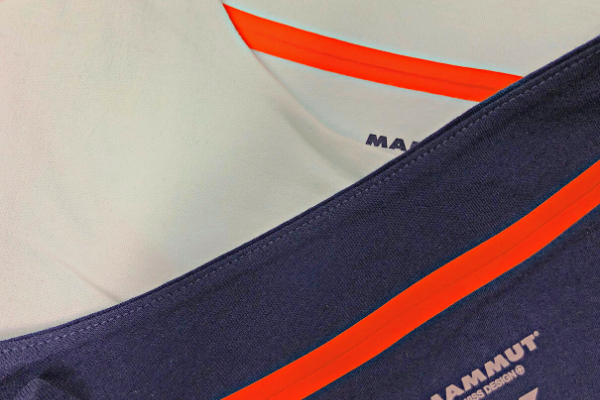

FUNCTIONAL CLOTHING

SPORTSWEAR

SLEEPWEAR

THERMAL CLOTHING

HOME TEXTILE

ON-DEMAND PRODUCTION

How we do things

Discover new opportunities and develop your products in a way you've never tried before. In our factory of more than 52,000 square meters, we run a full production cycle, advising you every step of the way and working together to achieve the best result.

Product design and sampling

Experienced designers and constructors at Utenos Trikotažas will help you create models of your products, while technologists will find the technical solutions that best meet your needs. We’ll help you choose yarns, create print patterns and produce sample designs.

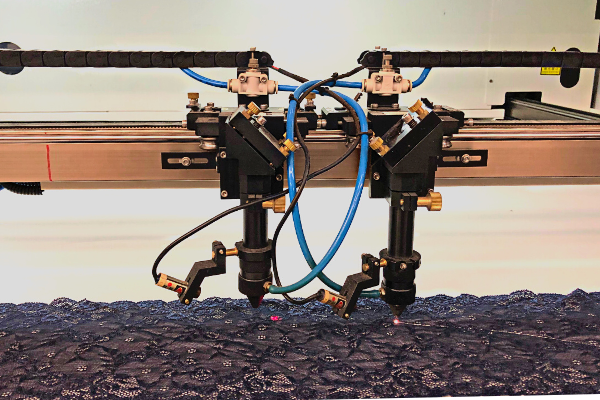

Cutting

Once the patterns and materials have been approved, we move on to the cutting stage. Innovative automatic cutting equipment allows to prepare products for sewing quickly and efficiently. We work with batches ranging from small, medium to very large.

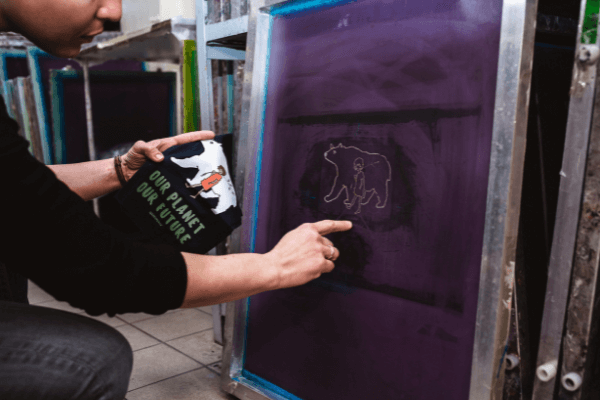

Decoration technologies

Sewing

Probably the most important stage of the entire production process at the largest unit of Utenos Trikotažas. It is staffed by experienced professionals in their field – seamstresses, craftsmen and quality inspectors. We produce more than 3 million garments a year.

Quality control

The vertically integrated production process allows quality control at all stages of production. We carry out compliance tests for various standards in our factory laboratory. We also offer the possibility to test any fibre or material before production starts. Our most commonly performed tests cover the following:

- Yarns

- Materials

- Coloured materials

- Washing

Packaging and logistics

We deliver the products so they can be immediately displayed on shelves or sent to customers: we take care of the labels, packaging and logistics to the agreed delivery point.

Our Brands